Technical Services

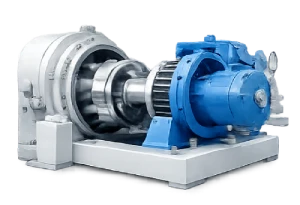

Centrifugal Pumps

Metrocon delivers complete lifecycle services for centrifugal pumps, covering installation, commissioning, troubleshooting, and precision alignment. Our expertise includes overhung, between-bearing, and vertical suspended pumps across all major OEMs. We perform in-house and on-site overhauls, seal replacement, bearing inspection, and rotor dynamic balancing.

Enquire Now

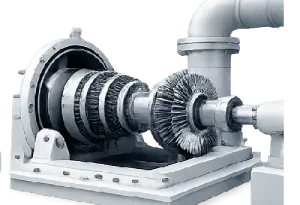

Steam Turbine

Metrocon provides comprehensive steam turbine services from installation and start-up to major overhauls and diagnostics.

Our scope includes rotor alignment, valve testing, bearing replacement, and gland sealing inspection. We perform vibration analysis, thermal expansion monitoring, and overspeed trip testing.

Enquire Now

Centrifugal Compressor

Metrocon supports all types of centrifugal compressors with installation, commissioning, and shutdown maintenance services. Our capabilities include seal system testing, bearing inspection, hot alignment, and gearbox inspection. We execute complete shop overhauls, rotor balancing, diaphragm alignment, and bundle extraction.

Enquire Now

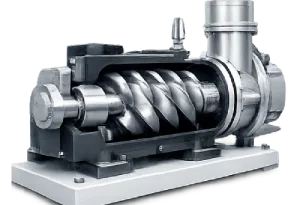

Screw Compressor

Metrocon offers specialized services for oil-free and oil-flooded screw compressors across all OEMs. Our scope includes installation supervision, alignment, filter replacement, and cooler servicing. We perform major overhauls including screw inspection, bearing replacement, timing gear setting, and casing repair. Our services maximize uptime, efficiency, and compressor life.

Enquire Now

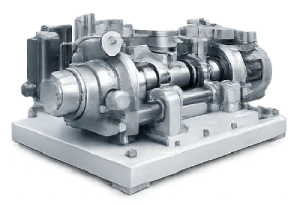

Reciprocating Compressor

Metrocon delivers expert services for piston and plunger-type reciprocating compressors.Our work includes installation, alignment, valve inspection, packing replacement, and cylinder assessment.We conduct dimensional checks, NDT inspections, wear analysis, and OEM-tolerance verification.These services ensure safe operation and long-term compressor reliability.

Enquire Now

Specialist- Screw Compressor

Metrocon’s specialist team provides multi-brand screw compressor inspection and health assessment services. We evaluate operating conditions and recommend optimized maintenance strategies at competitive cost. Our expertise covers all major OEMs, including oil-free, oil-lubricated, centrifugal, and reciprocating compressors.

Enquire Now

Vibration Inspection & Fault Diagnosis

We conduct detailed vibration inspections to assess the condition of rotating equipment. Advanced diagnostic techniques help identify bearing, alignment, and mechanical faults.

Our studies support predictive maintenance for pumps, motors, compressors, and turbines.

Modal & ODS Analysis

We perform advanced Modal and Operating Deflection Shape (ODS) analysis for complex issues. Dynamic characteristics such as natural frequencies, mode shapes, and damping are identified. These studies help detect resonance-related problems during operation. The analysis supports accurate root cause identification and corrective action planning.

Motor Health Analysis

Motor health is evaluated using Electrical Signature Analysis and Motor Circuit Analysis. Both energized and de-energized testing methods are applied for complete assessment. This helps identify electrical, winding, rotor, and insulation-related defects early. The service enhances motor reliability and reduces unexpected electrical failures.

Infrared Thermography

Infrared thermography detects abnormal heat patterns in electrical and mechanical systems. It supports condition-based maintenance and early fault identification.

Applications include electrical panels, mechanical friction points, and process equipment.

Field Rotor Dynamic Balancing

We perform in-situ dynamic balancing at normal operating speeds. Rotor unbalance is corrected as per ISO 1940 allowable limits. The service is suitable for low- to high-speed rotating equipment. It significantly reduces vibration, bearing wear, and mechanical stress.

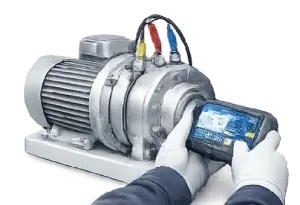

Laser Shaft Alignment

Precision laser alignment ensures accurate coupling between rotating shafts. Live field corrections are performed for optimal machine alignment. We handle long-distance alignments up to 20 meters with high accuracy. Proper alignment improves equipment life and reduces energy loss.

Please do not hesitate to contact us should you have any questions.

Contact Us

+966 50 847 0000

P.O.BOX 977, King Faisal St. AL JUBAIL 31951, Kingdom of Saudi Arabia

Saturday-Thursday: 8am – 5pm

Get Started

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text

© 2025, All rights reserved.