Centrifugal Pumps

Metrocon delivers complete lifecycle services for centrifugal pumps, covering installation, commissioning, troubleshooting, and precision alignment. Our expertise includes overhung, between-bearing, and vertical suspended pumps across all major OEMs. We perform in-house and on-site overhauls, seal replacement, bearing inspection, and rotor dynamic balancing.

Enquire Now

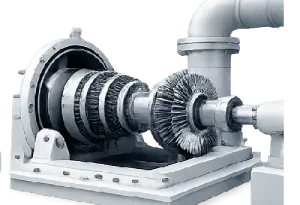

Steam Turbine

Metrocon provides comprehensive steam turbine services from installation and start-up to major overhauls and diagnostics.

Our scope includes rotor alignment, valve testing, bearing replacement, and gland sealing inspection. We perform vibration analysis, thermal expansion monitoring, and overspeed trip testing.

Enquire Now

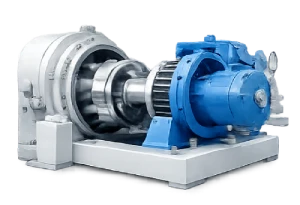

Centrifugal Compressor

Metrocon supports all types of centrifugal compressors with installation, commissioning, and shutdown maintenance services. Our capabilities include seal system testing, bearing inspection, hot alignment, and gearbox inspection. We execute complete shop overhauls, rotor balancing, diaphragm alignment, and bundle extraction.

Enquire Now

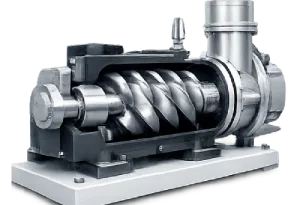

Screw Compressor

Metrocon offers specialized services for oil-free and oil-flooded screw compressors across all OEMs. Our scope includes installation supervision, alignment, filter replacement, and cooler servicing. We perform major overhauls including screw inspection, bearing replacement, timing gear setting, and casing repair. Our services maximize uptime, efficiency, and compressor life.

Enquire Now

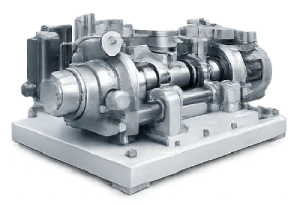

Reciprocating Compressor

Metrocon delivers expert services for piston and plunger-type reciprocating compressors.Our work includes installation, alignment, valve inspection, packing replacement, and cylinder assessment.We conduct dimensional checks, NDT inspections, wear analysis, and OEM-tolerance verification.These services ensure safe operation and long-term compressor reliability.

Enquire Now

Specialist- Screw Compressor

Metrocon’s specialist team provides multi-brand screw compressor inspection and health assessment services. We evaluate operating conditions and recommend optimized maintenance strategies at competitive cost. Our expertise covers all major OEMs, including oil-free, oil-lubricated, centrifugal, and reciprocating compressors.

Enquire Now

Training

Vibration Analysis

This training program builds competency in vibration measurement, analysis, and diagnosis. Courses progress from basic data collection to advanced fault analysis and corrective action. Participants gain hands-on experience with real industrial rotating equipment. Certifications are aligned with ISO 18436 standards through Mobius Institute.

Field Lubrication

This course focuses on correct lubrication practices for rotating and static equipment. Participants learn lubricant selection, contamination control, and lubrication intervals. Training emphasizes reducing bearing failures and improving asset life. Field-oriented practices ensure immediate application in industrial environments.

Ultrasound Analysis

Ultrasound training enables early detection of mechanical, electrical, and process faults. Participants learn applications such as bearing lubrication, leak detection, and electrical inspection. The course supports proactive maintenance and condition-based decision making. Hands-on sessions improve accuracy in real-world monitoring scenarios.

Infrared Thermography

This certification teaches thermal imaging principles for condition monitoring applications. Participants learn to identify abnormal heat patterns in electrical and mechanical systems. The course supports predictive maintenance, safety, and quality inspections. Training aligns with industry standards and real plant inspection practices.

Asset Reliability Practitioner

This program focuses on improving reliability and performance of industrial assets. Participants learn reliability-centered maintenance and asset management strategies. The course integrates condition monitoring with maintenance optimization techniques. It supports long-term operational excellence and cost-effective asset management.

Precision Alignment

This training covers laser-based shaft alignment techniques for rotating machinery. Participants learn live correction methods and alignment best practices. The course helps reduce vibration, energy loss, and mechanical wear. Practical sessions ensure accurate field alignment skills.

Dynamic Balancing

This course trains participants in in-situ rotor balancing techniques. Balancing methods are taught for low- and high-speed rotating equipment. Participants learn to correct unbalance as per ISO 1940 standards. The training improves machine reliability and reduces vibration-related failures.

Please do not hesitate to contact us should you have any questions.

Contact Us

+966 50 847 0000

P.O.BOX 977, King Faisal St. AL JUBAIL 31951, Kingdom of Saudi Arabia

Saturday-Thursday: 8am – 5pm

Get Started

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text

© 2025, All rights reserved.